Industrial coatings can be applied to a wide range of materials and components, to provide resistance to: wear, erosion, cavitation, corrosion, abrasion or heat.

We offer HVOF, Wire Arc Spraying and Flame Spraying industrial coating options in house. HVOF coatings can also used to provide electrical conductivity or insulation, lubricity, high or low friction, sacrificial wear, chemical resistance and many other desirable surface properties. It has huge scope to extend the life of new components or through the use of tried and tested techniques, to repair and re-engineer worn or damaged components.

Coating Types

HVOF Thermal Spray Coating

Wire Arc Spraying

Flame Spraying

Coating Materials

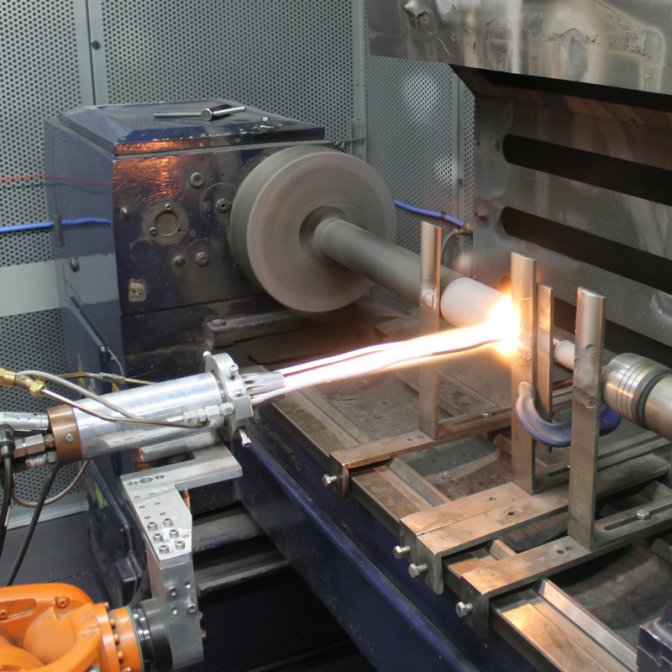

Our HVOF Coating Process

HVOF is an additive process that fires powdered metal at the substrate at extremely high velocities. This process creates an strong bond, often impregnating the base metal. The coating is applied using state of the art HVOF gun, utilising a KUKA robotic arm to ensure repeatability and absolute control of the coating process. After the coating is applied we will often apply grinding and/or polishing to ensure a smooth surface finish.

Frequently Asked Questions

Suitable Components

A very wide range of components could benefit from HVOF applied Coatings. We regularly coat parts such as: Gate and Ball Valves, Rock Drilling Bits, Down Hole Tools, Hydraulic Piston Rods, Print Roller, Fluid Seals, Turbine Plades, Impellors, and more. The process can also be used for the repair and reclamation of worn parts.

Size of Components

The High Velocity nature of the coating process makes it quite destructive and not necessarily suitable for smaller parts. B&B have successfully coated half inch Ball Valves with the aid of custom jigging but we would still expect a small amount of scrap during this process. Get in touch to see if the process is right for your application.

Coating Specifications

Confusingly, the same coating makeup is often given several brand names. Some examples of this would be WOKA, Amdry, Diamalloy and Metco. In most cases we are able to combine our materials to match the makeup of a branded coating without the need to buy from a specific provider.

Prep & Finishing

B&B are able to supply a complete coated component and our in-house processes include shot peening, coating, quality assurance as well as grinding and lapping. This means we do not need to sub work out to other providers, further saving you time and money.