Inspection & Bend Test Approval

Here at B and B Precision, we employ various methods to assess HVOF Thermal Spray coatings encompassing Hardness Tests, Metallographic Tests, Pull Off Tests & Bend Tests. We also conduct additional in-process examinations to verify optimal operations. By consistently monitoring equipment, nozzles, and powder flow, we ensure the process remains within established parameters.

In this blog we look at the results of HVOF Sample Bend Tests…

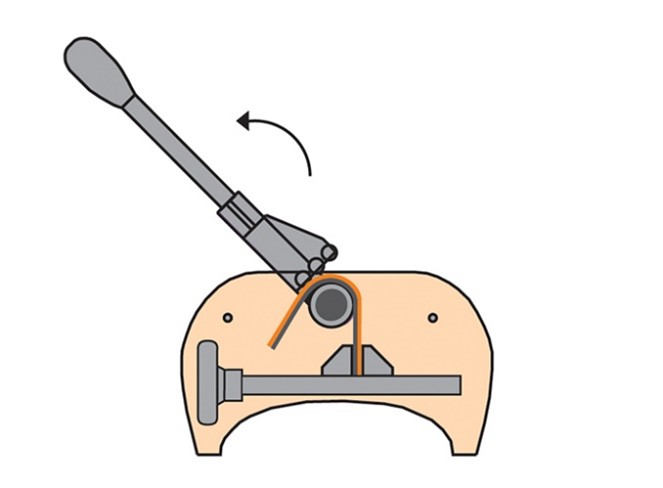

Figure 1

Using the Elcometer 1506 Cylindrical Bend Tester equipment, the coated sample is secured in a vice, and the handle is then pulled over the sample as shown below.

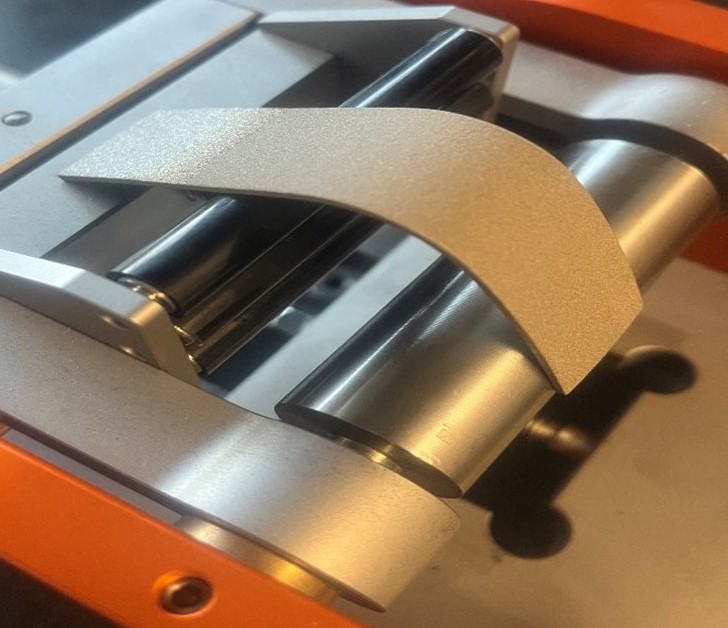

Figure 2

While bending, the coating is considered acceptable if it stays intact without flaking or spalling from the sample. In addition, the presence of transverse cracks complies with acceptable norms outlined in all customer specifications.

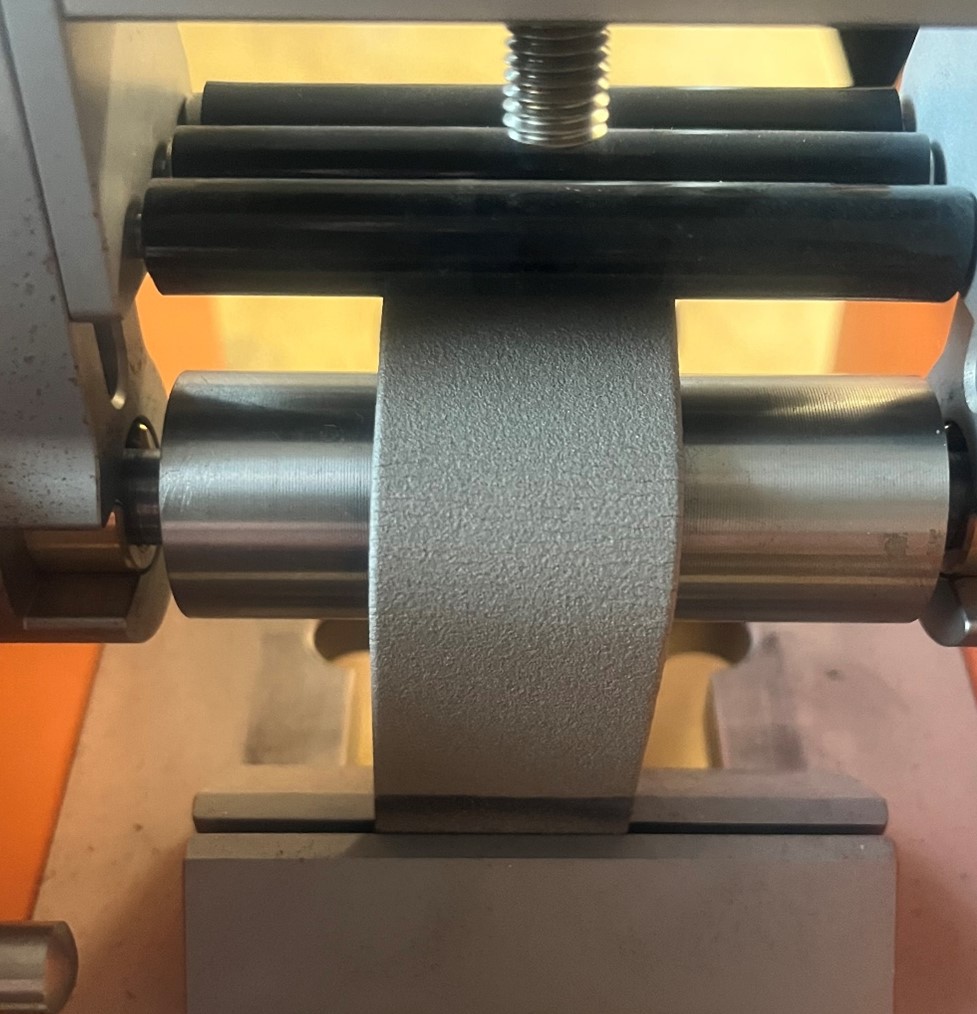

Figure 3

This is a close up of the ‘passed’ sample which shows how fine the cracks are. It is a common misconception that the coating can come off however this isn’t the case. We carried out this test to highlight the bond strength and therefore debunk this theory.

Get in touch with us today, we can give you all the information you’ll need on the right materials for your application as well as giving you an overview on costs and turnaround. We provide HVOF applied coatings including Stellite 6, Tungsten Carbide, Ceramics and many more. We are ISO certified and based in Huddersfield, West Yorkshire. Email us at mail@bandbprecision.co.uk or call 01484866386. Check out our Facebook Facebook and Instagram B&B Precision Engineering (@b_and_b_precision_engineering) • Instagram photos and videos

More blog posts here: Blog – B&B Precision Engineering (bandbprecision.co.uk)

No responses yet